- Industrial tools for professionals

- Dutch Engineering

- N° 1 in Safety

- Premium Quality

HIGH SPEED STEEL

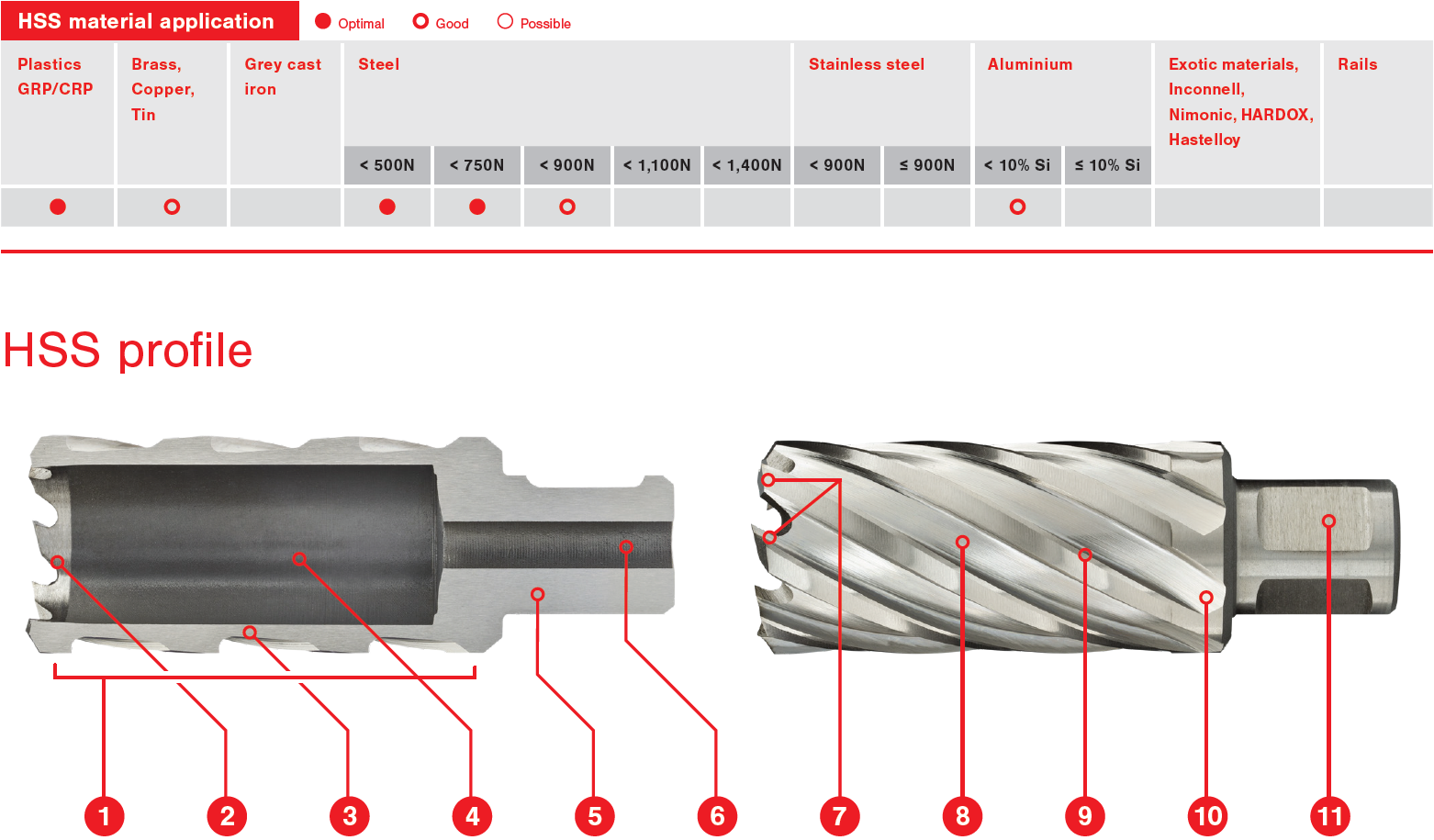

HSS annular cutters, with unique teeth geometry, provide clear cutting, fast feed rate, less vibration, smooth hole surface, and long tool life. They are faster and more efficient than twist drills. HSS annular cutters can be used on all kinds of magnetic drilling machines and are suitable for drilling steel, copper, aluminum, stainless steel, and plastic, in either plate or pipe form. The entire range is available in various specifications and can be customized to your requirements.

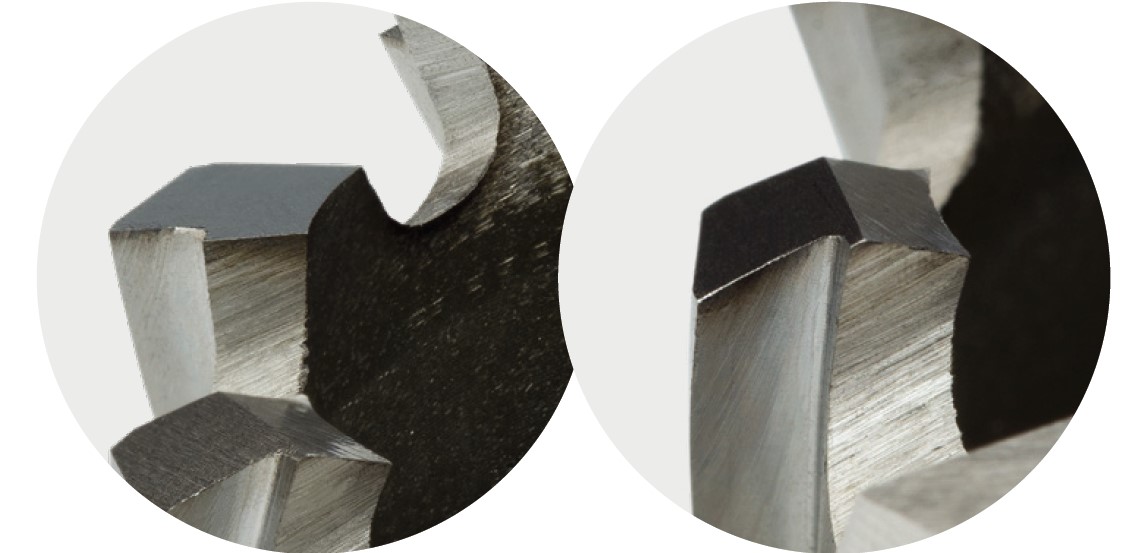

HSS (High Speed Steel) annular cutters are designed with a unique teeth geometry that allows for a cleaner and quicker cutting process. The two distinct types of teeth work together to deliver a fast feed rate with minimal vibration. This results in a smooth hole surface and extends the overall tool life, making these cutters an efficient and reliable choice for precise cutting tasks.

- Stage hardening: Combines maximum hardness at the teeth with superior strength at the cutter body, reducing breakage to a minimum.

- Inner ground cutting teeth: Helps stable “setting” of the cutter, reduces friction during drilling, and aids slug ejection.

- Optimized wall thickness: Matched to the diameter of the cutter, combining the best cutting time with strength.

- Tapered inside fitment: Prevents the cutter from getting stuck. Guarantees slug ejection with the correct pilot pin.

- Precise shank fitment: Ensures maximum interchangeability and close-tolerance drilling without run-out.

- Precise pilot pin fitment: Provides perfect centering, easy pin retraction, and controlled lubricant flow.

- Altering "continuous pre-cut" teeth geometry: Generates faster and more stable drilling performance and results in clear cuts of the highest precision and smooth, burr-free finishes.

- Optimized spiral flute angles: Provide ideal chip removal.

- Specially designed blades: Ensure optimum stability and heat reduction.

- Flutes and teeth matched to diameter: Deliver the best tooth load and superior cutting speeds.

- Precision ground shanks: Guarantee perfect fitment of both cutter and pilot pin, increasing safety, stability, and hole accuracy.

HIGH SPEED STEEL - COBALT

Euroboor HSS-Cobalt annular cutters are made of Molybdenum-Chromium-Vanadium-Tungsten alloy High Speed Steel with an additional 5% Cobalt (HSS-M35), which results in higher hardness while minimizing the chance of cutter breakage. The HSS-Cobalt annular cutter is specifically designed to remain cool when cutting holes. All flutes are fully ground, ensuring super-fast feed rates and smooth holes in hard materials, providing better chip clearance and higher cutting performance. The M35 HSS-Cobalt annular cutter is widely used in the metalworking industry for its superior red hardness compared to conventional high-speed steels. This enables shorter cycle times in production environments due to higher cutting speeds.

Shank

Euroboor annular cutters are standard equipped with high-precision Weldon shanks. Depending on cutter size and specification: 19.05 mm (3/4") or 31.75 mm (1 1/4").